CAUTION: USE OF WORKING LOADS

Because of the wide range of rope use, rope condition, exposure to the several factors affecting rope behavior, and the degree of risk to life and property involved, it is impossible to make blanket recommendations as to working loads. However, to provide guidelines, working loads are tabulated for rope in good condition with appropriate splices, in non-critical applications and under normal service conditions.

The Cordage Institute Formula for working load is:

Working Load = Minimum Breaking Strength/Safety Factor

A higher working load may be selected only with expert knowledge of conditions and professional estimate of risk. Also, if the rope has not been subject to dynamic loading or other excessive use, has been inspected and found to be in good condition, is to be used in the recommended manner; if the application does not involve elevated temperatures, extended periods under load, or obvious dynamic loading (see explanation below) such as sudden drops, snubs or pickups. For all such applications and for applications involving more severe exposure conditions, or for recommendations on special applications, call Jay at 763-263-9835.

**Many uses of rope involve serious risk of injury to personnel or damage to valuable property. This danger is often obvious, as when a heavy load is supported above one or more workmen. An equally dangerous situation occurs if personnel are in line with a rope under tension. Should the rope fail, it may recoil with considerable force. Persons should be warned against the serious danger of standing in line with any rope under tension. IN ALL CASES WHERE SUCH RISKS ARE PRESENT, THERE IS ANY QUESTION ABOUT THE LOADS INVOLVED OR QUESTIONS ABOUT THE CONDITIONS OF USE, THE WORKING LOAD SHOULD BE SUBSTANTIALLY REDUCED AND THE ROPE PROPERLY INSPECTED.

DYNAMIC LOADING VOIDS NORMAL WORKING LOADS

Normal working loads are not applicable when the rope is subject to significant dynamic loading. Whenever a load is picked up, stopped, moved or swung there is an increased force due to dynamic loading. The more rapidly or suddenly such actions occur, the greater the increase will be. In extreme cases, the force put on the rope may be two, three or even more times the normal involved. Examples could be picking up a tow on a slack line or using a rope to stop a falling object. Therefore, in all such applications such as towing lines, lifelines, safety lines, climbing ropes, etc. working loads as given DO NOT APPLY.

Users should be aware that dynamic effects are greater on a low elongation rope such as polyester than on a high elongation rope such as nylon, and greater on a shorter rope than on a longer one. The working load ratios listed contain provision for very modest dynamic loads. This means, however, that when this working load has been used to select a rope, the load must be handled slowly and smoothly to minimize dynamic effects and avoid exceeding the provision for them.

EFFECT OF TEMPERATURE ON TENSILE STRENGTH

The tensile strength charts apply to ropes tested at normal room temperature (70°F). Ropes have lower tensile strengths at higher temperatures. 30°F (or more) lower at the boiling point of water (212°F) and continuing on down to zero strengths for nylon and polyester at 490°F and 300°F for polypropylene.

Also, continued exposure at elevated temperatures causes permanent damage. TENSILE STRENGTHS shown are average based on new ropes tested under laboratory conditions, minimum can vary by 10%.

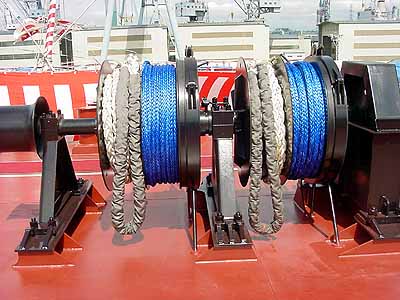

When you decide to purchase docklines, it is possible to be overwhelmed by the variety of rope available . If you are after rope to secure your boat to the dock, you can - and should - ignore most of those spools. Most marine cordage is for general or specialized use aboard sailboats, and the less it stretches, the more it gets revered by sailors. For docklines, however, sailors and power boaters alike need a rope that does stretch.

When you decide to purchase docklines, it is possible to be overwhelmed by the variety of rope available . If you are after rope to secure your boat to the dock, you can - and should - ignore most of those spools. Most marine cordage is for general or specialized use aboard sailboats, and the less it stretches, the more it gets revered by sailors. For docklines, however, sailors and power boaters alike need a rope that does stretch.